| HV37-15 Fast Recovery High Voltage Diode Data Sheet | ||||

| Parameter | Symbol | Unit | Test Conditions | Value |

| Repetitive Peak Backward Voltage | Vrrm | KV | Ta=25℃ Ir=2.0μA | 15 |

| Average Forward Current | If2(AV) | mA | Ta=40℃ In air | 250 |

| Average Forward Current | If2(AV) | mA | Ta=55℃ In oil | 150 |

| Backward Recovery Time | Trr | nS | 100 | |

| Surge Forward Current | Ifsm | A | 0.01S @ Half-Sine wave 50Hz | 15 |

| Operating Ambient Temperature | Ta | ℃ | -55~+125 | |

| Storage Temperature | Tstg | ℃ | -55~+125 | |

| Forward Peak Voltage | Vfm | V | ≥20 | |

| Backward Peak Current | Irrm1 | μA | @ Ta=25℃ VRM=VRRM | 2.0 |

| Irrm2 | μA | @ Ta=100℃ VRM=VRRM | 10.0 | |

| Absolute Maximum Ratings & Electrical Characteristics | ||||

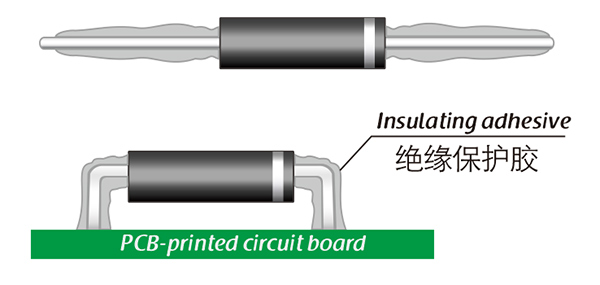

Here, suitable insulation adhesive materials can be selected based on the different usage situations of engineers.